This is something I’ve been working on recently. This is the brief I set myself.

Small format - small enough to work as a eurorack module

Minimal control count - ties into the need to keep it small

Minimum of 16 steps - expandable or a facility to chain more than one sequencer

No microcontrollers allowed - for the DIYer who isn’t a programmer

Off the shelf and easily obtainable components - mInly built around CMOS logic DIP parts still in production.

Low parts count - no brainier as long as I can get the functionality right.

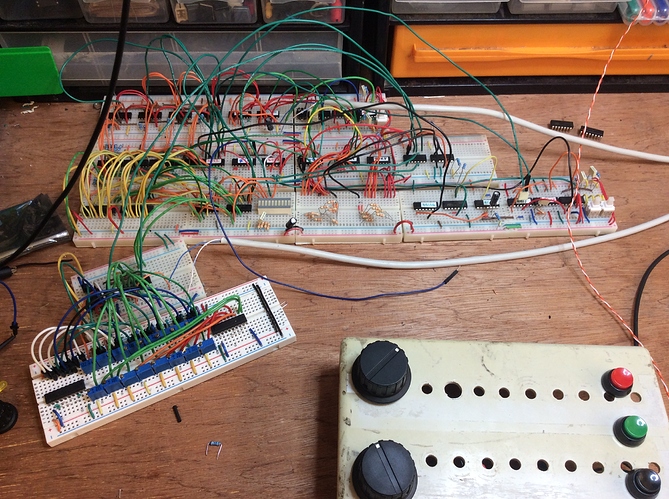

So far I’ve made good progress. I’ve got the heart of the sequencer breadboarded and running. Currently working on the control and interface side of things. Sequencer outputs quantized note cv’s across just over an octave. Octave shift per step is intended as well as ratcheting (up to 4 gates per step), sync output at 24 and 48 PPQN as well as pulse per step. There are a few other things I’m hoping to implement. I’ve got them roughed out but not prototyped yet.

The unit will be fairly spartan with just 4 controls for setting the 16 notes, play and programme modes with start, stop and record (programming mode) controls. If I add, say another set of 4 parameter knobs I can control more per step setting but then I’m up to 8 knobs and the eurorack footprint will be getting wider. I could possibly implement those extra per step settings with push buttons.

This isn’t a MIDI sequencer as there is no processor so it’s purely a CV and gate sequencer and a quantized one at that. Obviously the output doesn’t just have to hit a VCO tho.

Without getting into mission creep I recon I can implement ratcheting and per step gate length settings but there is the trade off with the controls. I’m imagining a clean and logical workflow rather than a ton of knobs. It’s a trade off but I feel there’s a happy medium to be struck.

What do you guys think? I know it’s a million miles from some of the midi sequencers on the market but it’s not aiming at competing with them, it’s more a small and easy to programmme little DIY box for sequencing short patterns but offers something more than a 4017 based sequencer, another DIY favourite, such as quantzing, more steps and less real estate as less controls are needed.