You can get a screw extraction kit, or you can get creative, both will probably take a little bit of effort.

If you have steady hands, you might be able to first protect the faceplate with some blue tape and a little bit of thin cardboard and then use a pair of channel-lock pliers to get a firm grip on the screwhead and manually turn it out.

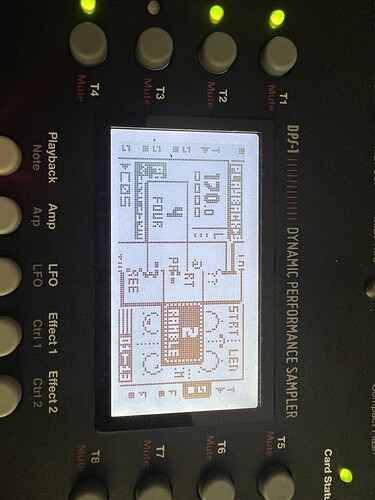

As far as your screen, once you get the face off you could unplug the ribbon cables and clean the copper parts of the terminals with some contact cleaner. I don’t know if that’s an actual physical issue with the screen or whatever drives the screen, or maybe a bug in your firmware causing it.

You could run the error test by booting into startup mode and after you check the results, try backing up everything and then reloading firmware and test for results on a blank project, just see if it comes back.

It’s often recommended that if you have the original CF card that you try another one if project data is getting corrupted and I don’t know if this is project data, but if you have the original CF card still then I guess that’s something to consider as well.

Elektron sent me some screws to replace the rusted ones on my digitone and one of them was stuck and the head was stripped. I had to use a grinding disc on a rotary tool to take down the edges of the round screw and make two flat parallel sides and then as suggested above, I used a channel lock plier to grab it and manually turned it out.

Of course I protected the faceplace first, but it wouldn’t come out and I had to get creative, so there is definitely some risk and effort involved and you may want to look into the screw extraction kit, although usually you have to purchase more than what you need because the kits come with more than one size even if you only need the one for your application.

I think a lot of those kits also involve drilling down into your screwhead so if it’s at the point where you aren’t comfortable doing this kind of stuff yourself, you may want to hand it off to someone else to get the screw removed.

Sorry, that’s probably all I got. I would normally recommend using something like liquid wrench or WD40 to try and soak into the threads and make it so they might be easier to break loose, but I’m not confident that those types of products won’t stain the finish on your faceplate so I probably wouldn’t want to risk it unless I were desperate.

I’m looking for a picture of how I cut the head to make it work. You might not need to do all that, mine was pretty turfed though as you can see in this picture, the rust was making it really difficult to get it out and that’s why I had to grind on it a little.